SINGLE-PHASE PARALLEL SERIES

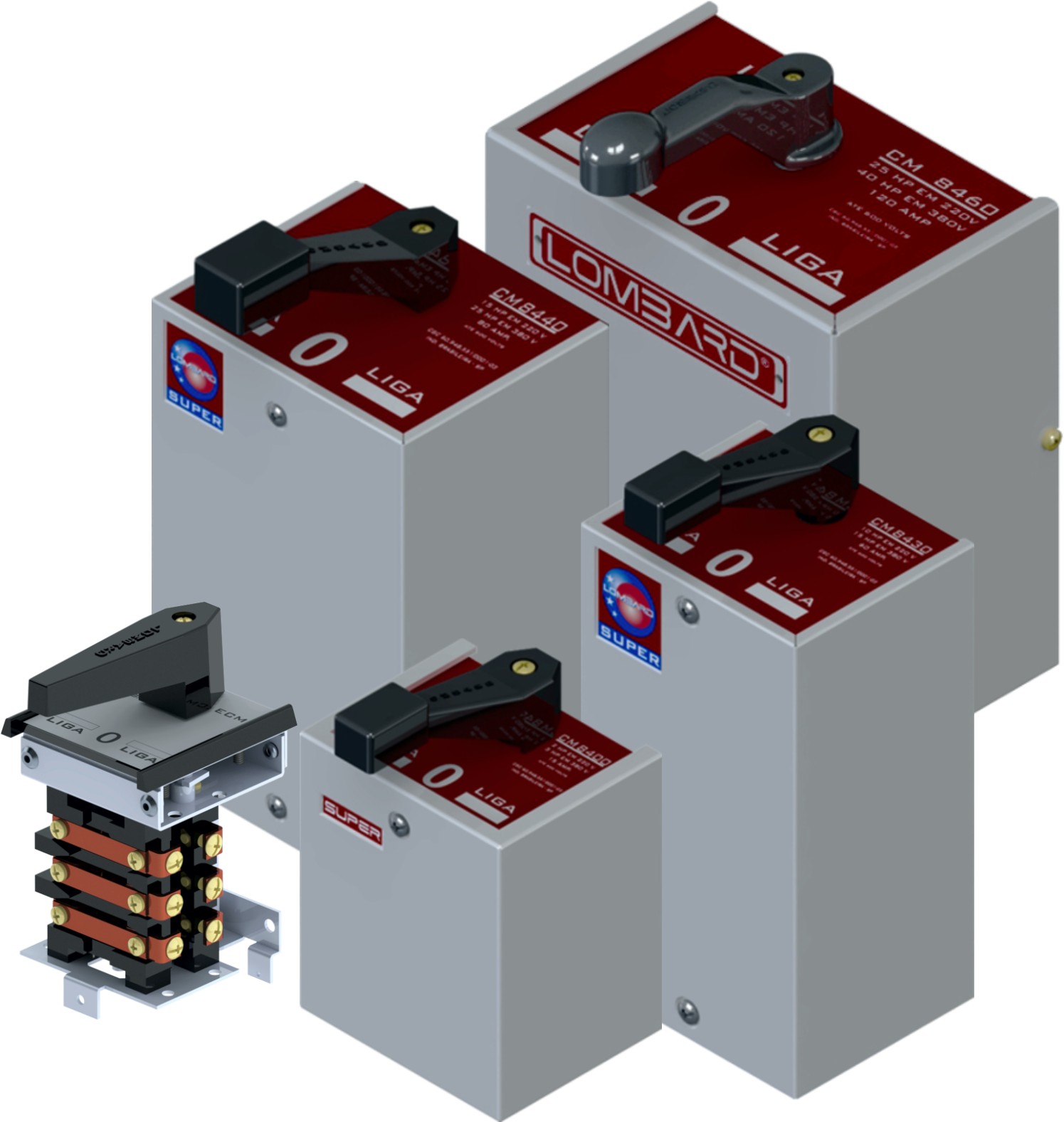

USE:

Starter switch with reduced voltage, which connects the different parts of each phase winding of the motor, initially in series for starting and then in parallel for normal operation.

For series-parallel starting, the motor must be restartable for two voltages, the lowest of which is equal to the mains voltage and the other is twice as high. This type of connection requires nine terminals on the motor and the most common nominal voltage is 220/440V, that is: during starting, the motor is connected in series configuration until it reaches its nominal speed and then switches to the parallel configuration.

In this type of starting, the current peak is reduced to 1/4 of that with direct starting. It must be borne in mind that in this type of connection, the engine starting torque is also reduced to 1/4 and, therefore, the machine must start practically empty.

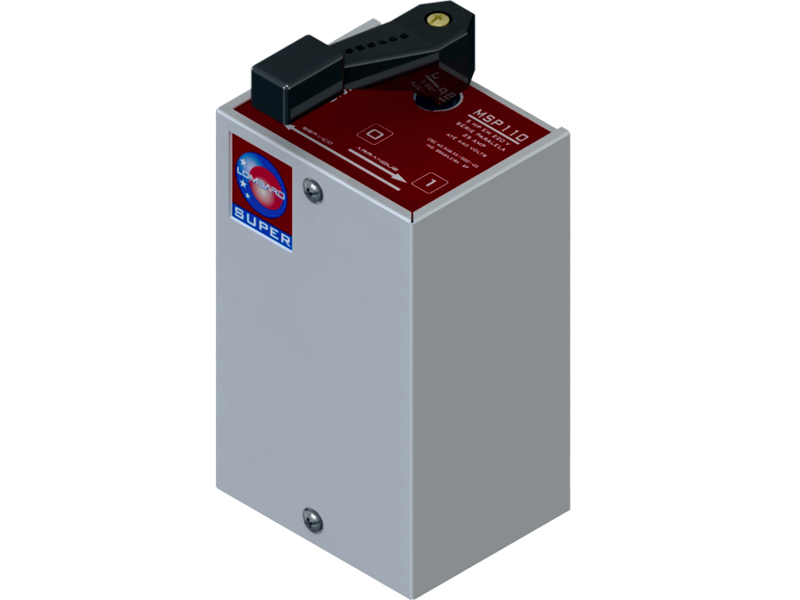

They are used to reduce the starting current of single-phase motors. The engine starts in two stages: when you turn the handle to the START position, the engine coils are connected in series; After acquiring sufficient rotation, the handle is placed in the SERVICE position in which the motor coils are connected in parallel, and the motor works at normal speed. For safety reasons, the handle is not locked in the START position.

APPLICATION:

Turning presses, eccentric presses, guillotine presses, machine tools in general, agricultural machinery, civil construction and others.